All's Well

1 of 10

It is December 26, 2012 at 4:00 pm. There was some scheduling difficulty in ensuring that at least one of us siblings was in Toronto in case Dad or his caregiver had a problem. So I delayed going on vacation by a day and a half, so it is very quiet here and I can catch up on the family web site and my pictures.

As we can see on the DadCam, there were no problems, Dad is having an afternoon nap and all's well.

2 of 10

But earlier in the week, one of the two heat pumps in Dad's condominium would only blow cold air, not a good thing in December (the heat pump is behind this panel, which is both the air intake and the access door). The thermostat is above and to the right of it.

A heat pump is like an air conditioner, except:

- Instead of blowing hot air outside, a heat exchanger transfers this heat to a building water supply.

- Using a 4-way valve, its operation can be reversed so it makes heat instead of cold.

3 of 10

Surprisingly, the condominium property manager informed me that owners are responsible for the maintenance and repair of the heat pumps, so I spent some time trying to find the service manual for it. All that the building pays for is a semi-annual inspection and air filter change (the filter is the tall grey thing mounted on the access panel, behind the swing-open door).

4 of 10

I was able to find the

company website, a

brochure, and a

manual for a similar unit, but as often happens, to ensure that only factory-trained technicians can repair the units (at exhorbitant rates, no doubt), the service manual was not available on the company website or elsewhere on the Internet.

5 of 10

But dang, I should at least understand what's broken so I will know if the repair guy is trying to take advantage of me, so I spent some time figuring out that you need to remove the front access cover, and also the entire door and frame (which is caulked to the wall). Then you can pull-out the refrigeration unit.

The shiny hoses are the water lines bringing the water from the supply riser to the heat exchanger, and the other hose is the return. Electrical plugs from below the electrical compartment connect to the blower fan unit and to the refrigeration unit.

6 of 10

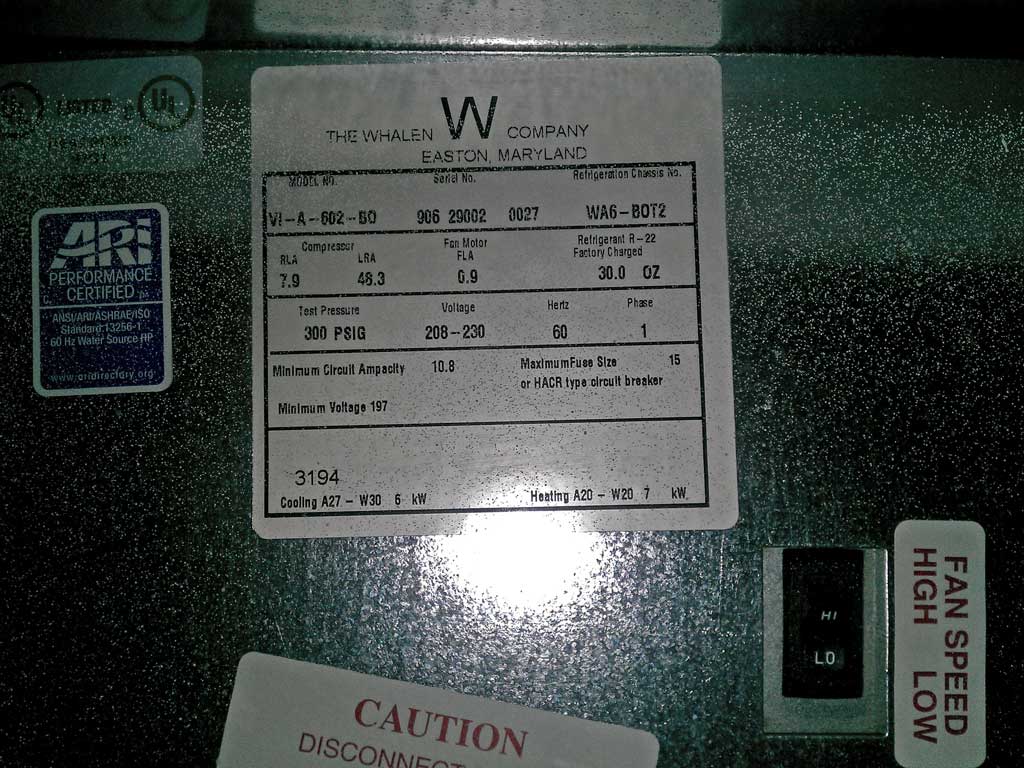

The heat pump is made by the Whalen Company, model VI-A-602-BO, it uses 208v AC from a 15-amp circuit.

7 of 10

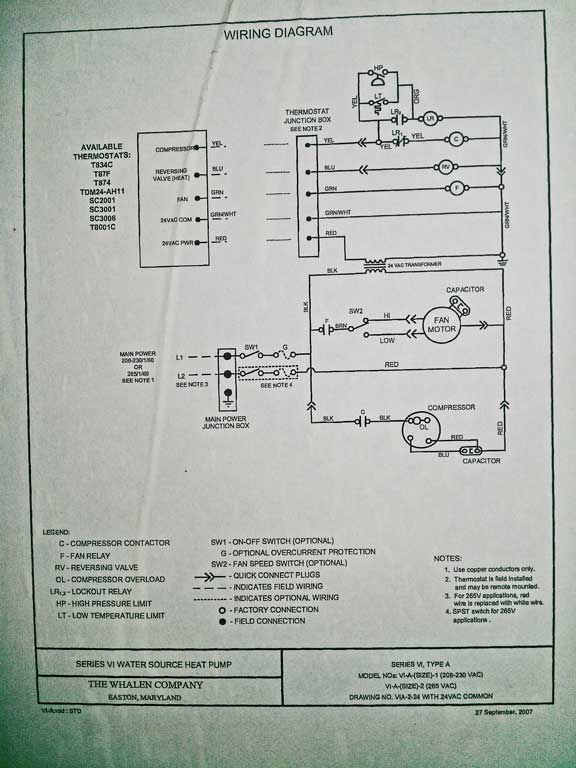

I spent some time following wires and listening for what clicks when you turn on the fan or the heat. Eventually it is clear that at the top-left is the 24V AC control voltage transformer, below that is the blower fan relay. To the right is the two-speed fan switch, and to the right of that is the power disconnect.

8 of 10

Fortunately, the back of the access panel has the circuit diagram. I was able to measure the motor's winding resistance (a bit tricky, since there is an open relay in series with it), which was 2 Ω, and as the manual for a similar unit said to expect between 2 Ω and 5 Ω, this was very good news (the compressor motor would be very difficult and expensive to replace).

9 of 10

I figured out you can pull out the refrigeration unit enough to remove the top cover without having to disconnect the water hoses. The symptoms were:

- When the blower fan switch on the thermostat was set to On, the fan relay clicked and the fan motor started and moved air, so that was all fine.

- When the thermostat was set to Heat there was a click, so the 4-way valve solenoid (the top of this is the brass disk towards the back) was working, so that probably was not the problem.

- When the thermostat called for heat, there was a click and a hum, but not the sound of the compressor motor running. So the compressor motor relay (this is at the front right side) was working, but the compressor motor was not starting (it just made a humming sound). Since the compressor motor's winding resistance was as expected, the compressor motor was probably not the problem.

- So the most likely problem would be the motor run capacitor, which is conveniently mounted at the front centre. And fortunately by my third visit I had brought my capacitance meter, and indeed the capacitor measured bad – it should have been 40 μF, but measured only a few nF.

I was able to find a replacement capacitor (not easy on a Saturday morning before Christmas, these are typically only available from industrial- and trade-supply companies, which don't have retail hours), but it was 45 μF. As the original capacitor was 40 μF +/-6% (so 37.7 μF to 42.4 μF), I figured the replacement capacitor should work (after all, this is big power stuff, not precision electronics), or at least not damage the motor.

So, I installed the replacement run capacitor, but bad news, still just a humming sound. The replacement capacitor I got happened to also have a 10 μF section, and I tried that, same thing, just a hum.

So the possibilities were; the compressor motor was siezed all along, the value of the replacement capacitor was too far from the required value, or I damaged the motor using the wrong-value replacement capacitor (ominously, the motor now seemed to measure only 1.5 Ω, but that might have been just because it had been hot when I measured it the first time). And I was going away for a few days soon, and while there is another heat pump for the other half of Dad's condominium, this did complicate things.

So it was time to call Bob's Refrigeration, which is the contractor used by the building. Bob promptly called me back, saying there would be a technician in the building anyways the next day (a total of three heat pumps in the building were found to be not working during the inspection), so painful as it was, I asked him to visit us too. Bob sounded to be a very gruff and no-nonsense guy (his website certainly gets to the point – just a phone number and hotmail e-mail address). He said the capacitor needs to be the exact value, and asked if it still measured the expected value after I found it didn't work (I hadn't checked this).

The summary is, the technician did come, he had the right capacitor, and that fixed it (he confirmed most problems are the capacitor, and he was surprised my replacement capacitor didn't at least start the motor, he also said running the fan on high in the winter – which is noisier – keeps the capacitor cooler so it should last longer).

So the good news is, the compressor motor was not damaged, the bad news is it costed $160 for the technician to do what I could have done for $15 had I had the time to get the right value capacitor.

But I did learn how to service heat pumps.

10 of 10

So all is well, later on December 26 Dad is watching television, and I visited later that evening (the Amica is on

Respiratory Alert though).